More Information About Servo motor drive base stepper motor drive adjustable support unit base

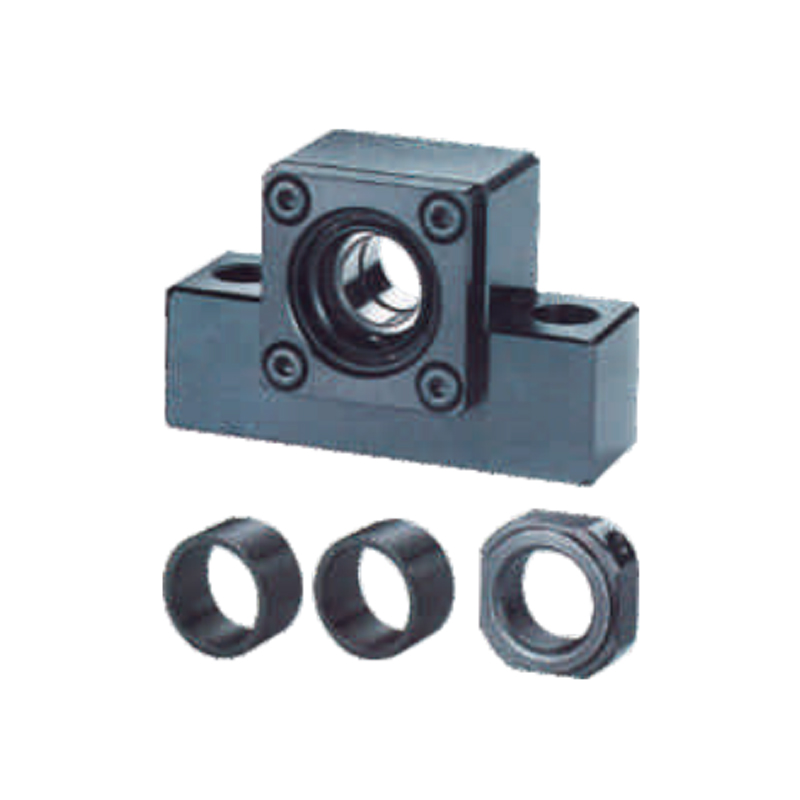

In the world of automation and precision engineering, Zhejiang Huayu Automation Technology Co., Ltd. stands as a beacon of innovation and quality. Their latest offering, the Servo and Stepper Motor Drive Base with Adjustable Support Unit, exemplifies their commitment to excellence. This product represents a leap forward in addressing the challenges associated with motor mount positioning, ensuring impeccable precision and simplifying the installation process.

Integration and Precision

The first aspect that sets this product apart is the integration of motor mount positioning holes and the bearing mounting hole. This integration process is a game-changer in terms of simplifying the assembly of motor and support units. It's a remarkable solution to ensure the maximum motor shaft and coupling axial alignment, as well as axial bearing hole and screw axis. By consolidating these elements, it overcomes the historical drawbacks of motor housing separation and the challenges associated with split bearing joint installation.

Enhanced Parallelism

Precise engineering often hinges on the delicate balance of parallelism. In this context, the parallelism between the bearing shaft and the mounting surface of the base reaches a remarkable 0.01/100. This meticulous attention to detail is designed to ensure the parallelism of the screw rod after installation. The result is flawless mechanical performance, setting the stage for impeccable precision in any application.

Product Variants for Versatility

Zhejiang Huayu's commitment to versatility and adaptability is evident in the range of product variants. The MBK17-110, MBK20-110, and MBK25-110 are ideally suited for 110 servo and stepping motors, ensuring compatibility with a wide range of applications. Meanwhile, the MBK20-130, MBK25-130, and MBK25B-130 variants are designed for 130 servo motors, expanding the horizons of applicability.

Applications and Industries

The Servo and Stepper Motor Drive Base with Adjustable Support Unit finds its place in a plethora of applications and industries. From CNC machining to robotics and automated production lines, the versatility and precision of this product make it an invaluable asset. In the aerospace sector, it guarantees accuracy in critical processes, while in pharmaceutical manufacturing, it ensures the dependable movement of materials and products.

Conclusion

In the intricate world of automation and precision engineering, the Servo and Stepper Motor Drive Base with Adjustable Support Unit from Zhejiang Huayu Automation Technology Co., Ltd. shines as an emblem of innovation. Its integration of motor mount positioning, dedication to parallelism, and adaptability to various motor types make it a sought-after solution for industries that demand precision and reliability. With Zhejiang Huayu's commitment to excellence, this product is set to propel engineering standards to new heights, ensuring that every application is marked by precision and performance.

Furthermore, Zhejiang Huayu's reputation for producing high-quality automation solutions and the Servo and Stepper Motor Drive Base with Adjustable Support Unit underscores the company's commitment to delivering products that meet and exceed the demands of the ever-evolving industrial landscape.

This versatile base unit not only simplifies the installation process but also enhances the operational efficiency of servo and stepper motor-driven systems. Its application extends to various sectors, from manufacturing and assembly lines to 3D printing and beyond. Zhejiang Huayu's dedication to precision engineering ensures that their products play a pivotal role in driving innovation and enhancing the capabilities of industries worldwide. With this product, the company stands as a reliable partner in achieving precision and excellence in the world of automation.

English

English 中文简体

中文简体 русский

русский Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)