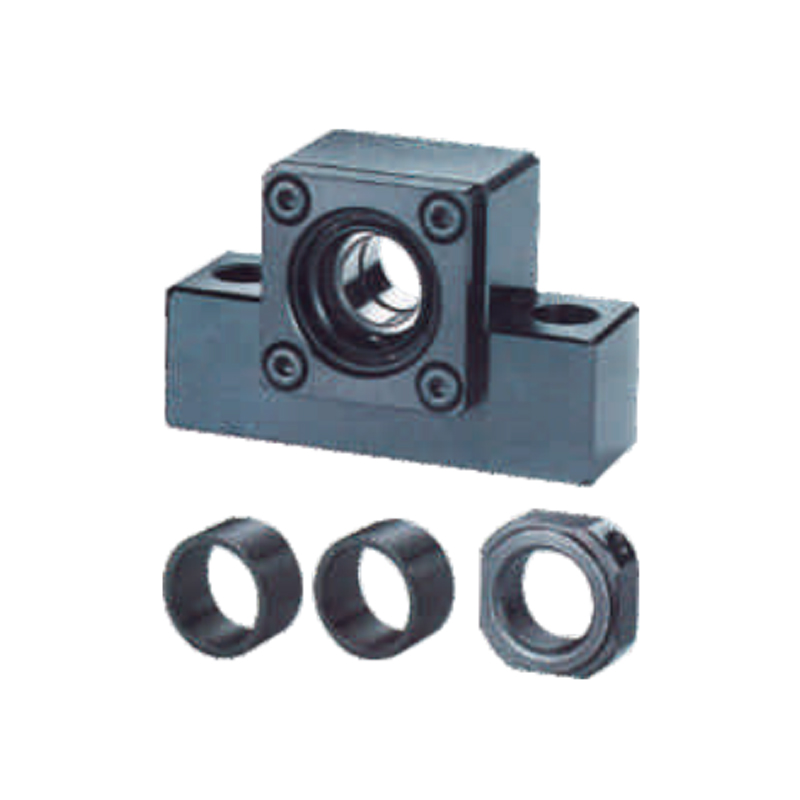

More Information About Linear bearing bracket ball screw custom design support seat ball screw endsupport

Zhejiang Huayu Automation Technology Co., Ltd. takes great pride in its innovative and precise engineering solutions. Building upon the technology described above, the company has introduced a groundbreaking product – the Linear Bearing Bracket Ball Screw Custom Design Support Seat. This cutting-edge device showcases Huayu's commitment to addressing industry-specific challenges with tailor-made solutions.

Custom Design Support Seat for Ball Screws

In the realm of industrial automation, precision and reliability are paramount. The Linear Bearing Bracket Ball Screw Support Seat is a testament to the company's dedication to providing products that meet these standards. Here's a closer look at how this innovative solution enhances the industry:

1. Integrated Motor Mount Positioning Holes and Bearing Mounting Hole: This design feature facilitates the seamless integration of motor mounts, ensuring maximum alignment of the motor shaft, coupling, axial bearing hole, and screw axis. Such integration eliminates the common challenges associated with motor housing separation during split bearing joint installation.

2. Optimal Parallelism: The parallelism between the bearing shaft and the mounting surface of the base reaches an astonishing 0.01/100. This level of precision ensures that once installed, the screw rod maintains perfect parallelism. This is critical for applications where precision and accuracy are non-negotiable.

Product Variants: Zhejiang Huayu Automation Technology Co., Ltd. has developed several variants of the Linear Bearing Bracket Ball Screw Support Seat to cater to diverse industry requirements:

- MBK17-80/MBK20-80: These variants are designed for adaptive motor models within the 80-750W servo motor range, ensuring compatibility and optimal performance.

- MBK17-86/MBK20-86: Specifically engineered for 86 stepping motors, these variants provide robust support for this category of motors.

- MBK20-90: This variant accommodates 90 servo motors and 90 reducers, making it versatile and adaptable to a range of industrial applications.

Applications Across Industries: The Linear Bearing Bracket Ball Screw Custom Design Support Seat has found applications across a wide array of industries, from manufacturing and robotics to aerospace and medical devices. Its precision and customizability make it a go-to choice for industries where exacting standards are required.

In conclusion, Zhejiang Huayu Automation Technology Co., Ltd.'s innovative Linear Bearing Bracket Ball Screw Custom Design Support Seat is a testament to their commitment to precision, reliability, and tailored engineering solutions. With its integration-friendly design and superior parallelism, it has found utility across various industries, further solidifying the company's reputation as a leader in industrial automation solutions. As technology continues to advance, solutions like these are paramount for maintaining and enhancing industrial efficiency and precision.

Zhejiang Huayu Automation Technology Co., Ltd. stands at the forefront of engineering excellence and innovation. Their Linear Bearing Bracket Ball Screw Custom Design Support Seat is a prime example of their dedication to delivering tailored solutions for the industrial automation sector.

This exceptional product, known for its integrated motor mount positioning holes and precise bearing mounting holes, addresses common challenges in motor installation and ensures optimal alignment. Its remarkable parallelism of 0.01/100 between the bearing shaft and mounting surface sets a new standard in precision.

The product's versatility, with variants accommodating different motor models, makes it a sought-after choice for applications ranging from manufacturing to medical devices. Zhejiang Huayu Automation Technology Co., Ltd. continues to be a trailblazer, creating solutions that drive industrial efficiency and precision forward.

English

English 中文简体

中文简体 русский

русский Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)