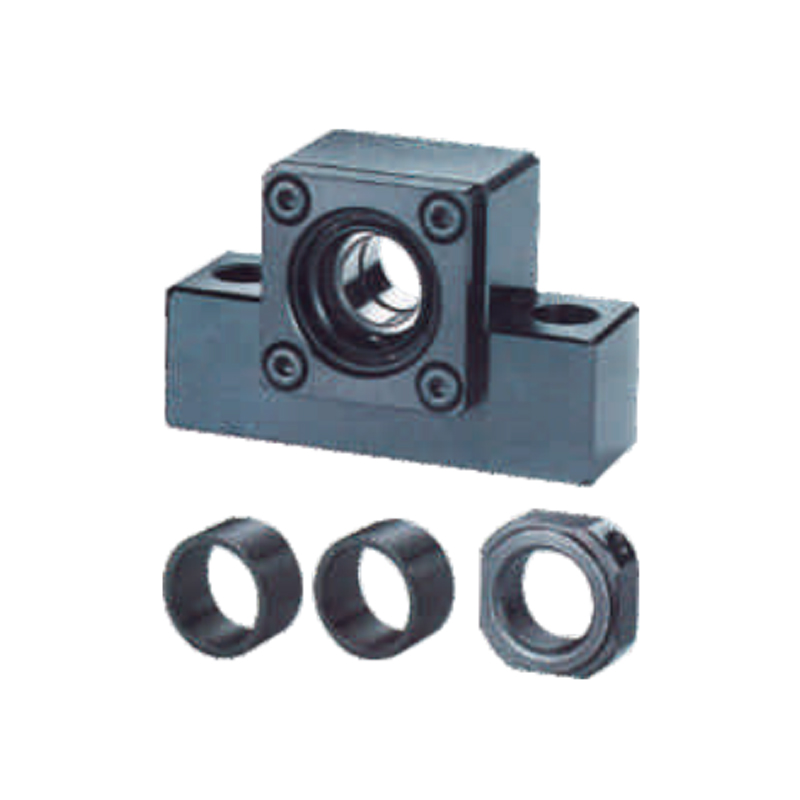

New precision ground ball screw SFY series low friction ball screw

-

Units:mmModel No. Shaft Diameter

(d)Lead

(I)Bead Diameter

(Da)Nut size Dynamic Load Rating

(Ca)Static Load Rating

(Coa)D A E B L W H X Q n SFYR1616-3.6 16 16 2.778 32 53 10.1 10 45 42 34 4.5 M6*1 1.8*2 1073 2551 SFYR2020-3.6 20 20 3.175 39 62 13 10 52 50 41 5.5 M6*1 1.8*2 1387 3515 SFYR2040-1.6 40 40 3.175 39 62 13 10 48 50 41 5.5 M6*1 0.8*2 653 1597 SFYR2550-1.6 50 50 3.969 47 74 15 12 58 60 49 6.6 M6*1 0.8*2 976 2495 SFYR2525-3.6 25 25 3.969 47 74 15 12 64 60 49 6.6 M6*1 1.8*2 2074 5494 SFYR3232-3.6 32 32 4.762 58 92 17 12 78 74 60 9 M6*1 1.8*2 3021 8690 SFYR4040-3.6 40 40 6.35 73 114 19.5 15 99 93 75 11 M6*1 1.8*2 4831 14062 SFYR5050-3.6 50 50 7.938 90 135 21.5 20 117 112 92 14 M6*1 1.8*2 7220 21974 -

Hot Product

-

Video Support

-

Engineer Communication

-

Online Service

Keep In Touch

Do You Have Any Question?

-

25 Feb, 2025

Understanding The Role Of China Linear Guide Rail In Precision Engineering

China Linear Guide Rail Ball Screw Nut Assembly Exporter Producer China Linear Guide Rail plays a crucial role in modern...

-

21 Feb, 2025

Exploring The Benefits Of China Linear Guide Rail For Industrial Automation

China Linear Guide Rail Ball Screw Nut Assembly Factory Manufacturer China Linear Guide Rail has become an essential com...

-

14 Feb, 2025

China Linear Guide Rail: Key Features And Applications In Modern Machinery

Sale Wholesale China Linear Guide Rail Ball Screw Nut Assembly China Linear Guide Rail has become an essential component...

More Information About New Precision Ground Ball Screw SFY Series Low Friction Ball Screw

SFY Ball screws are an essential component in modern machinery, providing precision and accurate motion with efficiency and reliability. These SFY ball screws are manufactured with advanced technology and undergo strict quality assurance checks.

SFY Ball screws are made of high-strength materials, including steel, stainless steel, and composites. Steel and stainless steel provide high durability and stability, while composites offer a lighter weight and improved wear resistance. The material composition of SFY ball screws is carefully selected to provide high strength, rigidity, and durability, ensuring optimal performance even in demanding environments.

Heat treatment is an essential process in the manufacture of SFY ball screws. The process involves heating and cooling the material to enhance its mechanical properties, such as strength and toughness, and improve its resistance to wear and fatigue. Heat treatment is a critical step in the production of SFY ball screws, ensuring their durability, strength, and reliability in high-stress applications.

The manufacturing process of SFY ball screws is precise and rigorous, ensuring high accuracy and consistency. It involves a series of steps, including milling, cutting, grinding, and polishing to produce the final product. These steps are performed by experienced technicians, who use advanced machinery and techniques to ensure that each SFY ball screw meets the required specifications.

A strict quality assurance system is implemented throughout the manufacturing process of SFY ball screws. The system includes inspection at every step of the manufacturing process, ensuring that each component of the SFY ball screw meets the required specifications.

The final product undergoes a rigorous quality control check to ensure that it meets the necessary standards for performance, accuracy, and durability. The strict quality assurance system ensures that SFY ball screws are reliable and high-performing, meeting the expectations of modern machinery.

SFY Ball screws offer several advantages, including:

High reliability - SFY Ball screws are manufactured with advanced technology and undergo strict quality assurance checks, ensuring they are reliable and durable.

Precision and accuracy - SFY Ball screws provide precise and accurate motion, resulting in high-quality production and efficiency.

Low friction - SFY Ball screws have minimal friction, resulting in efficient and smooth motion.

High load capacity - SFY Ball screws can handle heavy loads, making them ideal for heavy-duty applications.

Long lifespan - SFY Ball screws have a long lifespan, providing durable and reliable performance.

SFY Ball screws are used in a wide range of applications, including:

Industrial machinery - SFY Ball screws are commonly used in industrial machinery such as CNC machines, lathes, and milling machines to provide precise and accurate linear motion.

Robotics - SFY Ball screws are used in robotics to provide precise and efficient movement, resulting in accurate and efficient operation.

Aerospace - SFY Ball screws are used in aerospace applications, such as missile guidance systems, where precision and reliability are crucial.

Medical equipment - SFY Ball screws are used in medical equipment such as surgical robots and imaging systems, where precision and accuracy are essential.

Overall, SFY ball screws are an essential component in modern machinery, providing precision, reliability, and accuracy. The material composition, heat treatment, manufacturing process, and quality assurance system ensure that SFY ball screws meet the required specifications for performance, accuracy, and durability. The benefits of SFY ball screws include high reliability, precision and accuracy, low friction, high load capacity, and long lifespan. By embracing these benefits, manufacturers can improve the efficiency, quality, and profitability of their operations.

English

English 中文简体

中文简体 русский

русский Español

Español