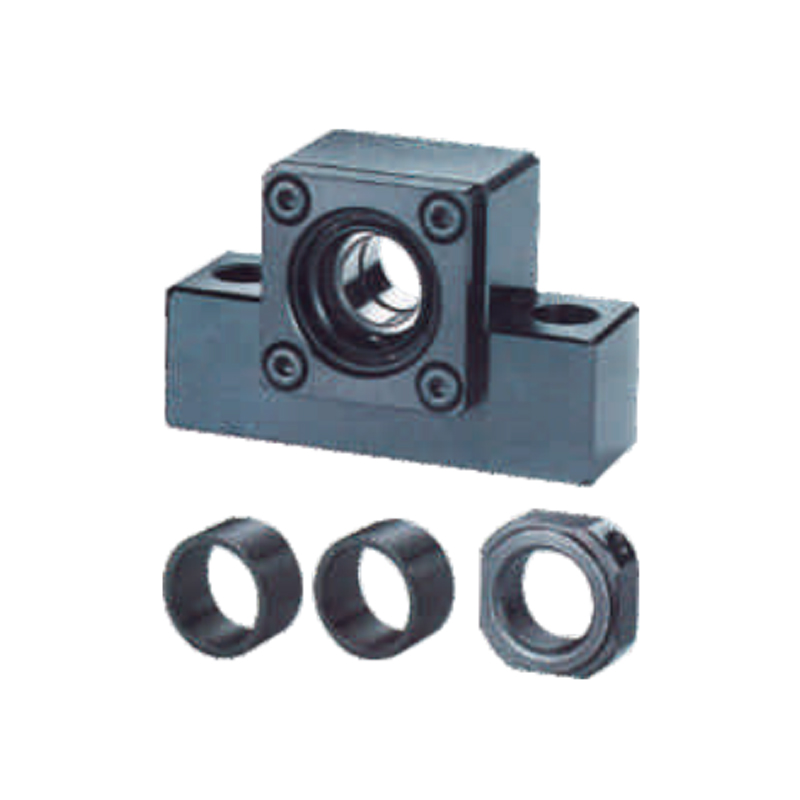

Large pitch linear bearing ball screw with nut SFS custom series

-

Units:mmModel No. Shaft Diameter

(d)Lead

(I)Bead Diameter

(Da)Nut size Dynamic Load Rating

(Ca)Static Load Rating

(Coa)D A B L W H X Q n SFSR1205-2.8 12 5 2.5 24 40 10 31 32 30 4.5 M6*1 2.8*1 661 1216 SFSR1210-2.8 10 2.5 24 40 10 48.5 32 30 4.5 M6*1 2.8*1 642 1287 SFSR1605-3.8 15 5 2.778 28 48 10 38 38 40 5.5 M6*1 3.8*1 1112 2507 SFSR1610-2.8 10 2.778 28 48 10 47 38 40 5.5 M6*1 2.8*1 839 1821 SFSR1616-1.8 16 2.778 28 48 10 45 38 40 5.5 M6*1 1.8*1 552 1137 SFSR1616-2.8 16 2.778 28 48 10 61 38 40 5.5 M6*1 2.8*1 808 1769 SFSR1620-1.8 20 2.778 28 48 10 57 38 40 5.5 M6*1 1.8*1 554 1170 SFSR2005-3.8 20 5 3.175 36 58 10 40 47 44 6.6 M6*1 3.8*1 1484 3681 SFSR2010-3.8 10 3.175 36 58 10 60 47 44 6.6 M6*1 3.8*1 1561 3833 SFSR2020-1.8 20 3.175 36 58 10 57 47 44 6.6 M6*1 1.8*1 764 1758 SFSR2020-2.8 20 3.175 36 58 10 77 47 44 6.6 M6*1 2.8*1 1118 2734 SFSR2505-3.8 25 5 3.175 40 62 10 40 51 48 6.6 M6*1 3.8*1 1650 4658 SFSR2510-3.8 10 3.175 40 62 12 65 51 48 6.6 M6*1 3.8*1 1638 4633 SFSR2520-2.8 20 3.969 40 62 12 72 51 48 6.6 M6*1 2.8*1 1206 2695 SFSR2525-1.8 25 3.175 40 62 12 70 51 48 6.6 M6*1 1.8*1 843 2199 SFSR2525-2.8 25 3.175 40 62 12 95 51 48 6.6 M6*1 2.8*1 1232 3421 SFSR3205-3.8 32 5 3.175 50 80 12 42 65 62 9 M6*1 3.8*1 1839 6026 SFSR3210-3.8 31 10 3.969 50 80 13 62 65 62 9 M6*1 3.8*1 2460 7255 SFSR3220-2.8 20 3.969 50 80 12 80 65 62 9 M6*1 2.8*1 1907 5482 SFSR3232-1.8 32 3.969 50 80 13 84 65 62 9 M6*1 1.8*1 1257 3426 SFSR3232-2.8 32 3.969 50 80 13 116 65 62 9 M6*1 2.8*1 1838 2329 SFSR4005-3.8 40 5 3.175 63 93 15 45 78 70 9 M8*1 3.8*1 2018 7589 SFSR4010-3.8 38 10 6.35 63 93 14 63 78 70 9 M8*1 3.8*1 5035 13943 SFSR4020-2.8 20 6.35 63 93 14 82 78 70 9 M8*1 2.8*1 3959 10715 SFSR4040-1.8 40 6.35 63 93 15 105 78 70 9 M8*1 1.8*1 2585 6648 SFSR4040-2.8 40 6.35 63 93 15 145 78 70 9 M8*1 2.8*1 3780 10314 SFSR5005-3.8 50 5 3.175 75 110 15 45 93 85 11 M8*1 3.8*1 2207 9542 SFSR5010-3.8 48 10 6.35 75 110 18 68 93 85 11 M8*1 3.8*1 5638 17852 SFSR5020-3.8 20 6.35 75 110 18 108 93 85 11 M8*1 3.8*1 5749 18485 SFSR5050-1.8 50 6.35 75 110 18 125 93 85 11 M8*1 1.8*1 2946 8749 SFSR5050-2.8 50 6.35 75 110 18 175 93 85 11 M8*1 2.8*1 4308 13610 -

Hot Product

-

Video Support

-

Engineer Communication

-

Online Service

Keep In Touch

Do You Have Any Question?

-

25 Feb, 2025

Understanding The Role Of China Linear Guide Rail In Precision Engineering

China Linear Guide Rail Ball Screw Nut Assembly Exporter Producer China Linear Guide Rail plays a crucial role in modern...

-

21 Feb, 2025

Exploring The Benefits Of China Linear Guide Rail For Industrial Automation

China Linear Guide Rail Ball Screw Nut Assembly Factory Manufacturer China Linear Guide Rail has become an essential com...

-

14 Feb, 2025

China Linear Guide Rail: Key Features And Applications In Modern Machinery

Sale Wholesale China Linear Guide Rail Ball Screw Nut Assembly China Linear Guide Rail has become an essential component...

More Information About Large pitch linear bearing ball screw with nut SFS custom series

In the realm of precision engineering and motion control, the Large Pitch Linear Bearing Ball Screw with Nut SFS Custom Series, offered by Zhejiang Huayu Automation Technology Co., Ltd., stands as a testament to cutting-edge technology and innovation. These ball screws play a pivotal role in various industrial applications, enabling precise linear motion and exceptional performance. However, their durability and effectiveness hinge significantly on proper maintenance and lubrication.

The Significance of Lubrication

Lubrication is the lifeblood of any ball screw system. It serves as the protective barrier between metal components, ensuring smooth, low-friction movement. The importance of adequate lubrication cannot be overstated, especially in the context of the Large Pitch Linear Bearing Ball Screw with Nut SFS Custom Series. Here's why:

1. Friction Reduction: The ball screw mechanism relies on minimal friction to function optimally. Adequate lubrication reduces contact between metal surfaces, minimizing friction and heat generation, which can be detrimental to the system's efficiency.

2. Wear Prevention: Without proper lubrication, metal-to-metal contact can lead to premature wear and tear. Over time, this wear weakens the components and, in extreme cases, can lead to system failure. Lubrication acts as a protective shield, extending the life of the ball screw.

3. Efficiency and Accuracy: Well-lubricated ball screws operate with enhanced efficiency and accuracy. This is of utmost importance in precision applications where even minor deviations can result in significant quality issues.

Customization and Specialization

Zhejiang Huayu Automation Technology Co., Ltd. understands the diverse needs of industries and offers the Large Pitch Linear Bearing Ball Screw with Nut SFS Custom Series. These products can be tailored to suit specific requirements, whether it's in terms of length, diameter, or load capacity. Customization ensures that these ball screws seamlessly integrate into various applications, from CNC machines to aerospace systems.

Custom ball screws from the SFS series maintain the same high standards of quality and precision as their standard counterparts. However, this flexibility allows industries to implement these components precisely where needed, optimizing their processes and machinery for peak performance.

Maintenance and Lubrication Best Practices

To ensure that your customized Large Pitch Linear Bearing Ball Screw with Nut SFS Custom Series operates at its best, it's essential to follow maintenance and lubrication best practices:

1. Regular Inspection: Implement a routine inspection schedule to check for any signs of wear or insufficient lubrication. Early detection of issues can prevent costly breakdowns.

2. Proper Lubrication: Use the recommended lubricants and follow the manufacturer's guidelines for lubrication intervals. Zhejiang Huayu Automation Technology Co., Ltd. provides specific recommendations for their custom ball screws to ensure longevity and performance.

3. Clean Environment: Keep the working environment clean and free of contaminants that may compromise the lubrication or the ball screw's integrity.

In the realm of precision engineering, the Large Pitch Linear Bearing Ball Screw with Nut SFS Custom Series is a testament to innovation and performance. However, even the most advanced components require proper care and maintenance to fulfill their potential. Lubrication is a cornerstone of this maintenance, ensuring reduced friction, minimal wear, and enhanced efficiency. With the ability to customize these ball screws to fit specific needs, Zhejiang Huayu Automation Technology Co., Ltd. empowers industries to achieve precision and excellence, provided they pay attention to the critical role of lubrication in prolonging the life and performance of these systems.

English

English 中文简体

中文简体 русский

русский Español

Español