Ball screw SFU series high precision customization

-

Units:mm

Model No. Shaft Diameter

(d)Lead

(I)Bead Diameter

(Da)Nut size Dynamic Load Rating

(Ca)Static Load Rating

(Coa)Note D A B L W H X Q n SFUR1204-3 12 4 2.5 24 40 10 40 32 30 4.5 M6*1 1*3 451 709 ☆ SFUR1604-3 16 4 2.381 28 48 10 36 38 40 5.5 M6*1 1*3 488 940 SFUR1605-3 5 3.175 28 48 10 42 38 40 5.5 M6*1 1*3 666 1143 ☆ SFUR1605-4 5 3.175 28 48 10 50 38 40 5.5 M6*1 1*4 888 1525 ☆ SFUR1610-3 10 3.175 28 48 10 57 38 40 5.5 M6*1 1*3 716 1232 ☆ SFUR2004-3 20 4 2.381 36 58 10 42 47 44 6.6 M6*1 1*3 541 1187 SFUR2005-3 5 3.175 36 58 10 42 47 44 6.6 M6*1 1*3 749 1495 ☆ SFUR2005-4 5 3.175 36 58 10 51 47 44 6.6 M6*1 1*4 999 1994 ☆ SFUR2504-3 25 4 2.381 40 62 10 42 51 48 6.6 M6*1 1*3 605 1534 SFUR2505-3 5 3.175 40 62 10 42 51 48 6.6 M6*1 1*3 839 1935 ☆ SFUR2505-4 5 3.175 40 62 10 51 51 48 6.6 M6*1 1*4 1119 2581 ☆ SFUR2510-3 10 4.762 40 62 10 70 51 48 6.6 M6*1 1*3 1427 2771 ☆ SFUR2510-4 10 4.762 40 62 12 85 51 48 6.6 M6*1 1*4 1903 3695 ☆ SFUR3205-4 32 5 3.175 50 80 12 52 65 62 9 M6*1 1*4 1264 3402 ☆ SFUR3210-3 10 6.35 50 80 12 74 65 62 9 M6*1 1*3 2319 4575 SFUR3210-4 10 6.35 50 80 12 90 65 62 9 M6*1 1*4 3092 6101 SFUR4005-4 40 5 3.175 63 93 14 55 78 70 9 M8*1 1*4 1407 4341 SFUR4010-3 10 6.35 63 93 14 71 78 70 9 M8*1 1*3 2610 5834 SFUR4010-4 10 6.35 63 93 14 93 78 70 9 M8*1 1*4 3480 7779 SFUR5010-4 50 10 6.35 75 110 16 93 93 85 11 M8*1 1*4 3898 10325 SFUR6310-4 63 10 6.35 90 125 18 98 108 95 11 M8*1 1*4 4401 13611 SFUR6320-4 20 9.525 95 135 20 149 115 100 13.5 M8*1 1*4 7404 19008 SFUR8010-4 80 10 6.35 105 145 20 98 125 110 13.5 M8*1 1*4 4900 17366 SFUR8020-4 20 9.535 125 165 25 154 145 130 13.5 M8*1 1*4 8403 25345

Note: Those marked with a ☆ can be made with a left thread. -

Hot Product

-

Video Support

-

Engineer Communication

-

Online Service

Keep In Touch

Do You Have Any Question?

-

25 Feb, 2025

Understanding The Role Of China Linear Guide Rail In Precision Engineering

China Linear Guide Rail Ball Screw Nut Assembly Exporter Producer China Linear Guide Rail plays a crucial role in modern...

-

21 Feb, 2025

Exploring The Benefits Of China Linear Guide Rail For Industrial Automation

China Linear Guide Rail Ball Screw Nut Assembly Factory Manufacturer China Linear Guide Rail has become an essential com...

-

14 Feb, 2025

China Linear Guide Rail: Key Features And Applications In Modern Machinery

Sale Wholesale China Linear Guide Rail Ball Screw Nut Assembly China Linear Guide Rail has become an essential component...

More Information About Ball Screw SFU Series High Precision Customization

Customizing the High Precision SFU Series Ball Screw involves several factors to ensure the product meets specific requirements and delivers optimal performance. So how to customize the High Precision SFU Series Ball Screw? What factors need to be considered?

1. Precision Requirements: One of the key selling points of the High Precision SFU Series Ball Screw is its high precision. During customization, you can select different precision grades, such as C3, C5, or C7, based on the specific application requirements. Higher precision grades offer improved positioning accuracy and stability, making them suitable for applications demanding precise position control.

2. Length and Diameter: Another important factor is the length and diameter of the ball screw. Customization allows you to choose ball screws with different lengths and diameters to suit your application needs. Longer screws enable larger travel distances, while larger diameters provide higher rigidity and load-carrying capacity.

3. Material and Coating: The material and surface coating of the ball screw are also crucial customization factors. Typically, high-quality alloy steel or stainless steel is used to manufacture ball screws, ensuring excellent strength and wear resistance. Addition ally, special coatings such as hard chrome, black oxide, or ceramic coatings can be applied to enhance surface hardness and corrosion resistance.

4. Lead and Pitch: Lead and pitch are key parameters in customizing the ball screw. Depending on the application requirements, you can select different lead and pitch options. Larger leads allow for faster movement, while smaller leads provide higher resolution and positioning accuracy cy.

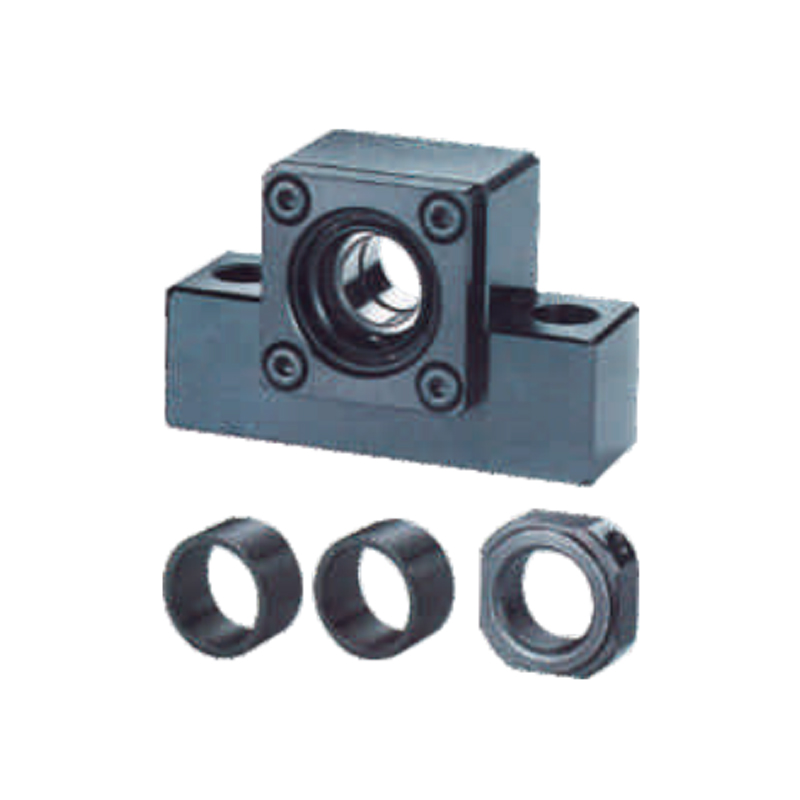

5. Support Type: The High Precision SFU Series Ball Screw can be customized with different support types, including end support, simple support, or fixed support. The choice of support type depends on factors such as load requirements, precision demands, and inst allation environment .

6. Dust Protection and Sealing: To enhance the lifespan and reliability of the ball screw, you can opt for additional features such as dust protection devices and seals. These add-ons prevent the ingress of dust, particles, and pollutants, ensuring smooth operation and extending the ball screw's service life.

7. Nut Type: Customization also includes selecting the appropriate nut type for the ball screw. The choice may include standard nuts, flanged nuts, or preloaded nuts, depending on the specific application's requirements for backlash, stiffness, and preload.

8. Lubrication Options: Lubrication plays a crucial role in maintaining the performance and longevity of the ball screw. Customization allows you to choose from various lubrication options, such as grease or oil lubrication, depending on the application conditions and maintenance preference s.

By offering customization options in terms of precision, length, diameter, material, coating, lead, pitch, support type, dust protection, sealing, nut type, and lubrication, the High Precision SFU Series Ball Screw caters to diverse industrial needs. precision, reliability, durability, and versatility make it an attractive choice for applications requiring accurate motion control and positioning in industries such as robotics, CNC machining, automation, and aerospace.

English

English 中文简体

中文简体 русский

русский Español

Español