More Information About Motor support base for servo motor ball screw bearing motor seat adjustable support unit base

In the realm of industrial automation, precision and stability are paramount. Zhejiang Huayu Automation Technology Co., Ltd. understands this, and their Motor Support Base for servo motors represents a significant step forward in achieving these goals. Let's delve deeper into this innovative product and explore its key features and benefits.

Integrating Excellence: Motor Support Base for Servo Motors

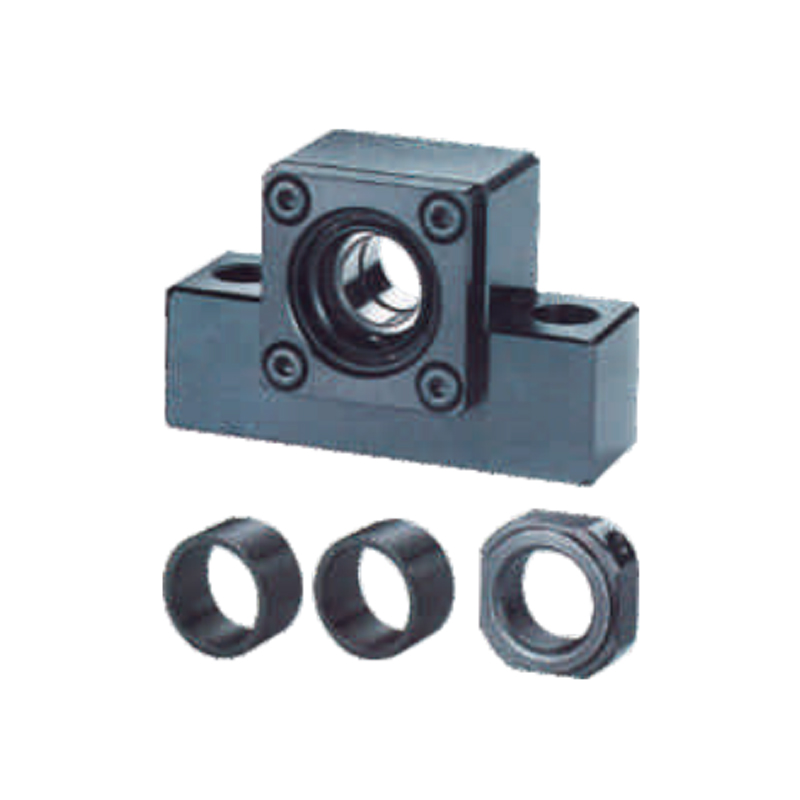

The Motor Support Base, often an unsung hero in the world of automation, plays a pivotal role in ensuring the smooth operation of various industrial processes. This vital component is designed to accommodate servo motors, ball screws, and bearings, offering unparalleled support for precision machinery. Zhejiang Huayu Automation Technology Co., Ltd. has created a game-changer with their Motor Support Base.

Integrated Mounting Holes: One of the standout features of this product is the integrated motor mount positioning holes and the bearing mounting hole. This integration process is a game-changer, eliminating the challenges of coaxial installation. This innovation ensures that the motor shaft, coupling, axial bearing hole, and screw axis are precisely aligned. In essence, it overcomes the shortcomings associated with the separation of the motor housing during the split bearing joint installation.

Precision Parallelism: The parallelism between the bearing shaft and the mounting surface of the base is a remarkable 0.01/100. This exceptional precision is maintained even after installation, ensuring the absolute parallelism of the screw rod. This level of precision is a testament to Zhejiang Huayu Automation Technology Co., Ltd.'s commitment to delivering quality solutions that meet the exacting demands of modern industries.

Adaptive Motor Models: To cater to a wide range of industrial needs, the Motor Support Base is available in various configurations. The MBK30-130, MBK35-130, MBK40-150, and MBK40-180 models are meticulously designed to accommodate different servo motor sizes, including 130 and 150 servo motors. This adaptability allows industries to choose the exact model that aligns with their specific requirements.

Applications and Beyond: The Motor Support Base for servo motors has found applications in diverse sectors, including manufacturing, robotics, and automation. It's become a cornerstone in industries where precision, stability, and seamless machinery operation are critical.

Zhejiang Huayu Automation Technology Co., Ltd. has raised the bar in industrial automation with their Motor Support Base for servo motors. By addressing the challenges associated with motor housing separation and ensuring unmatched precision and parallelism, this product has quickly become a go-to choice for industries that demand the utmost in quality and performance. The seamless integration of motors, ball screws, and bearings is not just an advancement; it's a revolution in the world of automation, offering a brighter, more precise future for manufacturing and industrial processes.

As industries evolve, the Motor Support Base from Zhejiang Huayu Automation Technology Co., Ltd. emerges as a critical component that paves the way for innovation. The integrated design, impeccable parallelism, and adaptability to various servo motor sizes empower businesses to push the boundaries of automation. It fosters precision and reliability, ensuring that even the most complex machinery operates seamlessly.

In the competitive landscape of modern manufacturing and industrial automation, Zhejiang Huayu's Motor Support Base is a testament to the pursuit of excellence. It stands as a symbol of the company's commitment to delivering cutting-edge solutions that drive industries forward. With every installation of the Motor Support Base, businesses embrace a future where precision, stability, and efficiency are not just goals but realities.

English

English 中文简体

中文简体 русский

русский Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)