More Information About Dc servo motor drive base stepper motor support adjustable ball screw seat unit base

Innovative Solutions: Zhejiang Huayu Automation Technology Co., Ltd. and the DC Servo Motor Drive Base Stepper Motor Support Adjustable Ball Screw Seat Unit Base

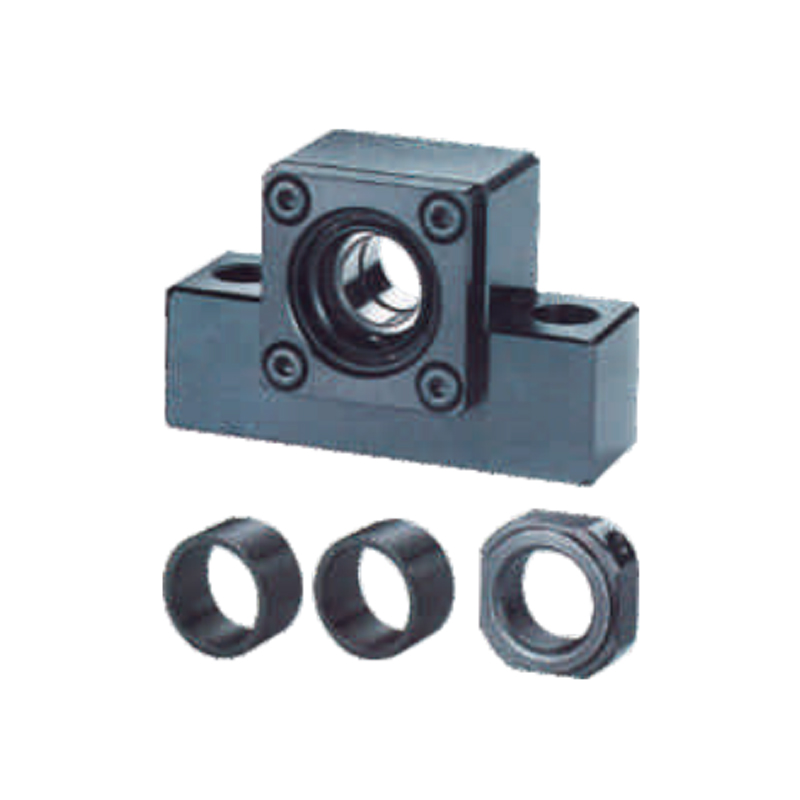

In the realm of automation and precision engineering, Zhejiang Huayu Automation Technology Co., Ltd. stands out as a pioneer in delivering innovative solutions that optimize the performance of various industries. One such groundbreaking product is the DC Servo Motor Drive Base Stepper Motor Support Adjustable Ball Screw Seat Unit Base. This component plays a vital role in enhancing the efficiency and precision of numerous applications.

Enhanced Integration for Seamless Operation

The essence of this product is its integrated design. The incorporation of motor mount positioning holes and bearing mounting holes into a single unit is a paradigm shift. This innovation ensures that the maximum motor shaft, coupling axial, and axial bearing hole are flawlessly aligned with the screw axis. In practical terms, this means a significant reduction in the complexities associated with the installation of split bearing joints, particularly in situations where motor housing separation was an obstacle.

The parallelism between the bearing shaft and the mounting surface of the base is a remarkable 0.01/100. This level of precision ensures that the screw rod maintains perfect parallelism post-installation, a crucial factor in ensuring seamless and precise mechanical operations. The adaptability of the DC Servo Motor Drive Base Stepper Motor Support Adjustable Ball Screw Seat Unit Base to various motor models, such as the 130 servo motor, 150 servo motor, and 180 servo motor, adds to its versatility and utility across different industries.

Applications Across Diverse Industries

The applications of this innovative product are far-reaching. In the manufacturing industry, it aids in the seamless operation of conveyor belts and robotic arms. In the medical sector, it finds application in high-precision surgical equipment, enabling doctors to perform intricate procedures with unparalleled accuracy. The automotive industry benefits from this technology by employing it in automated assembly lines and quality control systems.

Advancing Precision Engineering

Zhejiang Huayu Automation Technology Co., Ltd. has taken a significant step in advancing precision engineering with the DC Servo Motor Drive Base Stepper Motor Support Adjustable Ball Screw Seat Unit Base. This integrated solution eliminates the challenges of complex installations, streamlines mechanical operations, and enhances the performance of a wide array of applications.

In conclusion, this innovative product not only simplifies complex mechanical operations but also promotes precision and efficiency across industries. Zhejiang Huayu Automation Technology Co., Ltd. continues to push the boundaries of what is possible in automation and precision engineering, consistently providing solutions that make a tangible difference in the world of technology and manufacturing.

This integrated approach to motor and bearing alignment, offered by Zhejiang Huayu Automation Technology Co., Ltd., represents a significant leap in engineering innovation. The DC Servo Motor Drive Base Stepper Motor Support Adjustable Ball Screw Seat Unit Base streamlines complex installation processes, eliminating the challenges typically associated with split bearing joints and motor housing separations. Its adaptability to various servo motor models, including the 130, 150, and 180, opens doors to a multitude of applications across diverse industries. This product is not just a mechanical component; it's a testament to Zhejiang Huayu's commitment to pushing the boundaries of precision engineering and automation to make a lasting impact on the world of technology and manufacturing.

English

English 中文简体

中文简体 русский

русский Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)