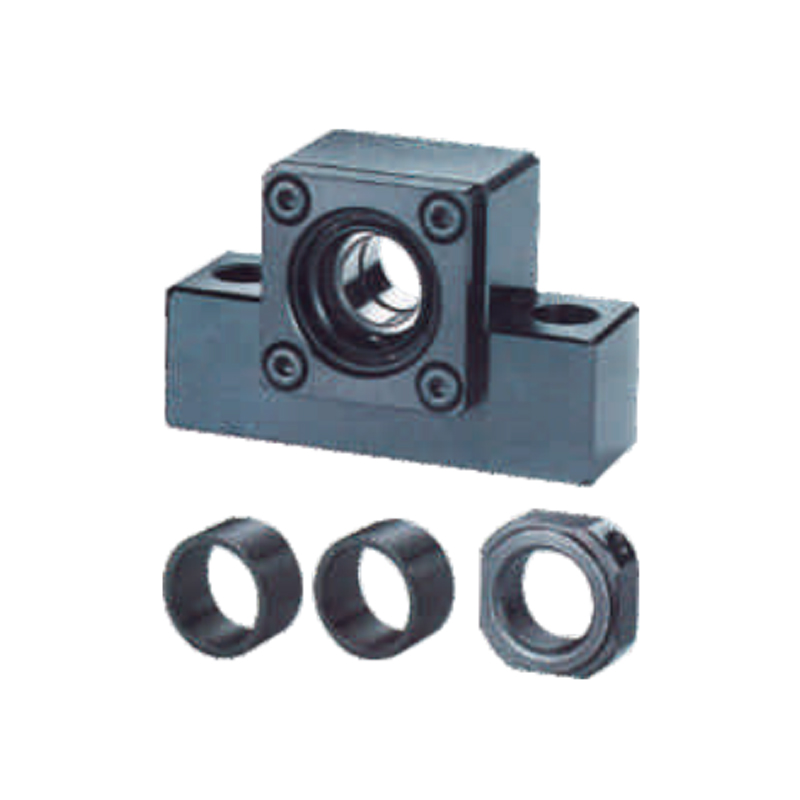

MGN-C-O Standard Type/MGN-H-O Extended Type Square Linear Guide

-

Note: 1kgf=9.81NModel Component Dimensions

(mm)Slider Dimensions

(mm)Rail Dimensions

(mm)Rail Fixing Bolt Size Basic Dynamic Load Rating Basic Static Load Rating Allowable Static Moment Weight H H1 N W B B1 C L1 L G GN M*l H2 WR HR D h d P E (mm) C(kN) C0(kN) MR

kN-mMP

kN-mMY

kN-mSlider

KgGuide Rail

Kg/mMGN5C-O 6 1.5 3.5 12 8 2 - 9.6 16 - 0.8 M2*1.5 1 5 3.6 3.6 0.8 2.4 15 5 M2*6 0.54 0.84 2 1.3 1.3 0.003 0.15 MGN5H-O 8 2 - 12.6 19 M2*1.5 0.67 1.08 2.6 2.3 2.3 0.004 MGN5HL-O - 6 7 12.6 19 M2.6-THRU 0.67 1.08 2.6 2.3 2.3 0.004 MGN7C-O 8 1.5 5 17 12 2.5 8 13.5 22.5 - ∅1.2 M2*2.5 1.5 7 4.8 4.2 2.3 2.4 15 5 M2*6 0.98 1.24 4.70 2.84 2.84 0.008 0.22 MGN7H-O 12 2.5 13 21.8 30.8 M2*2.5 1.37 1.96 7.64 4.80 4.80 0.012 MGN9C-O 10 2.2 5.5 20 15 2.5 10 19.4 30 - ∅1.4 M3*3 1.8 9 6.5 6 3.5 3.5 20 7.5 M3*8 2.01 2.84 13.05 8.97 8.97 0.012 0.38 MGN9H-O 15 2.5 16 29.3 39.9 M3*3 2.5 3.93 19.71 21.47 21.47 0.02 MGN12C-O 13 3 7.5 27 20 3.5 15 22 35 - ∅2 M3*3.5 2.5 12 8 6 4.5 3.5 25 10 M3.8 2.84 3.92 25.48 13.72 13.72 0.025 0.65 MGN12H-O 20 3.5 20 34.6 47.6 M3*3.5 4.27 5.9 38.4 37.49 37.49 0.047 MGN15C-O 16 4 8.5 32 25 3.5 20 26.7 41.3 4.50 M3 M3*4 3 15 10 6 4.5 3.5 40 15 M3*10 4.61 5.59 45.08 21.56 21.56 0.057 1.06 MGN15H-O 25 3.5 25 43.4 58 M3*4 6.37 9.11 73.5 57.82 57.82 0.088 -

Hot Product

-

Video Support

-

Engineer Communication

-

Online Service

Keep In Touch

Do You Have Any Question?

-

25 Feb, 2025

Understanding The Role Of China Linear Guide Rail In Precision Engineering

China Linear Guide Rail Ball Screw Nut Assembly Exporter Producer China Linear Guide Rail plays a crucial role in modern...

-

21 Feb, 2025

Exploring The Benefits Of China Linear Guide Rail For Industrial Automation

China Linear Guide Rail Ball Screw Nut Assembly Factory Manufacturer China Linear Guide Rail has become an essential com...

-

14 Feb, 2025

China Linear Guide Rail: Key Features And Applications In Modern Machinery

Sale Wholesale China Linear Guide Rail Ball Screw Nut Assembly China Linear Guide Rail has become an essential component...

More Information About MGN-C-O Standard Type/MGN-H-O Extended Type Square Linear Guide

To address the challenges of maintaining precision in motion control systems, it's crucial to look towards innovative solutions that minimize wear and optimize accuracy. In this pursuit, products like the MGN-C-O Standard Type and MGN-H-O Extended Type Square Linear Guide from Zhejiang Huayu Automation Technology Co., Ltd. have emerged as exceptional choices.

Traditional sliding guides often confront a common issue - the backflow of oil film, which inevitably results in poor movement accuracy for the platform. This can be a significant problem in applications where precision is paramount, such as CNC machining, 3D printing, or semiconductor manufacturing. Inadequate lubrication due to oil film backflow can lead to increased friction, wear, and ultimately, a decline in the overall accuracy of the system.

This is where the MGN-C-O and MGN-H-O Square Linear Guides come into play. These cutting-edge products offer a robust alternative, revolutionizing motion control systems by minimizing these accuracy-limiting factors. By doing so, they enable machines to maintain a high level of precision for extended periods.

One of the primary advantages of these linear guides is their use of rolling elements. Unlike sliding guides, which rely on direct contact between surfaces and are thus more prone to wear, rolling guides significantly reduce friction and wear. The rolling mechanism allows for smooth and consistent motion, contributing to an extended lifespan of the system and improved overall accuracy.

In addition to the wear-reduction properties, the MGN-C-O and MGN-H-O Linear Guides are built with meticulous attention to detail. Zhejiang Huayu Automation Technology Co., Ltd. ensures that these products meet rigorous quality standards. They are designed for easy installation, enhancing the user's experience and saving valuable time in setup.

Moreover, these linear guides come in two variations: the MGN-C-O Standard Type and the MGN-H-O Extended Type. This adaptability allows users to select the guide that best suits their specific application requirements. Whether it's a standard CNC machine, a high-precision medical device, or a specialized semiconductor manufacturing tool, these linear guides provide the versatility needed for a wide range of industries.

The MGN-C-O Standard Type offers the ideal combination of precision, compactness, and cost-effectiveness. It's an excellent choice for applications where space is limited, and precision is crucial, such as laboratory equipment or small CNC routers.

On the other hand, the MGN-H-O Extended Type is designed for situations that demand extra rigidity and stability. This extended version offers a larger footprint, providing enhanced support and precision. It's ideal for larger machines and heavy-duty applications, including industrial automation and woodworking machinery.

In conclusion, the MGN-C-O Standard Type and MGN-H-O Extended Type Square Linear Guides from Zhejiang Huayu Automation Technology Co., Ltd. represent a significant leap forward in motion control technology. By reducing wear and friction through rolling elements, these linear guides ensure that machines can maintain their accuracy over the long term. This not only extends the lifespan of the equipment but also guarantees consistent, precise results in a wide range of industrial applications. When precision is paramount, these linear guides are a dependable and forward-looking choice.

The MGN-C-O Standard Type and MGN-H-O Extended Type Square Linear Guides exemplify how innovation in motion control technology is transforming the industry. With rolling mechanisms, these guides reduce wear, extending system longevity and sustaining exceptional precision. Whether in CNC machining or industrial automation, they ensure consistent and accurate performance.

English

English 中文简体

中文简体 русский

русский Español

Español.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)