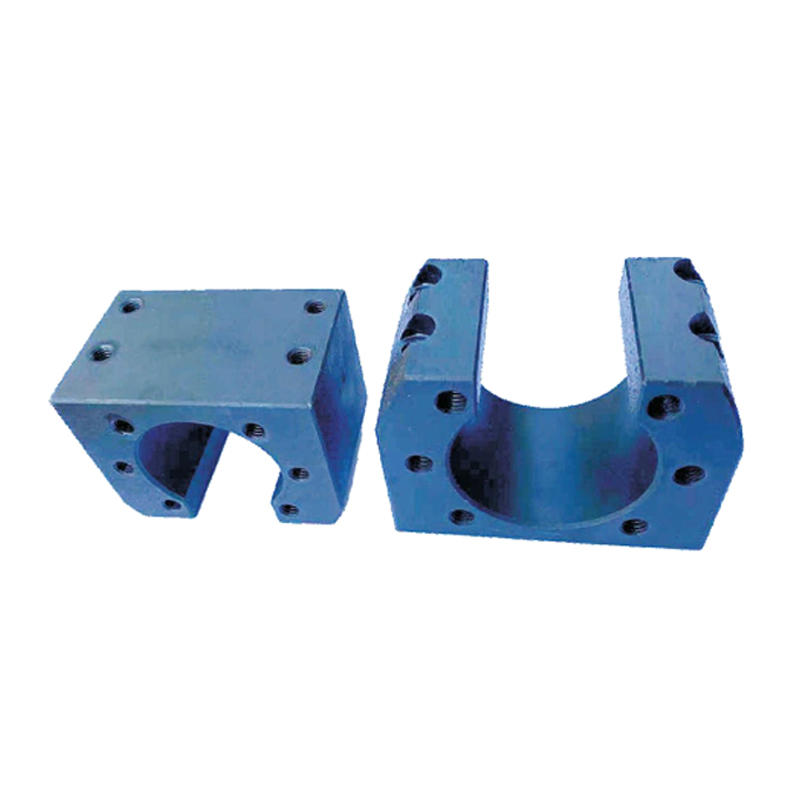

The MLM type iron ball screw nut mounting base adopts integrated processing, which can ensure the perpendicularity of the nut mounting surface and the base mounting surface to the maximum, and the perpendicularity of both sides reaches 0.01.

-

Model

Verticality

Texture of material

Weight

MLM1605

0.015

HT200

0.4

MLM1616

0.015

HT200

0.3

MLM2005

0.015

HT200

0.5

MLM2020

0.015

HT200

0.4

MLM2505

0.015

HT200

0.7

MLM2525

0.015

HT200

0.6

MLM3205

0.015

HT200

1

MLM3232

0.015

HT200

0.9

MLM4005

0.015

HT200

2.5

MLM4040

0.015

HT200

2.3

MLM5010

0.015

HT200

5

MLM5050

0.015

HT200

4.8

-

Unit:mm

T-shaped

Model

A

B

C

D+0.1

F

H±0.02

I

J

K

P

X

Y Through-hole

MLM1605

52

42

40

28

M5

20

17

18

40

38

M6

5.2

MLM1616

52

42

40

32

M4

20

17

18

40

42

M6

5.2

MLM2005

62

45

45

36

M6

23

18

20

48

47

M6

5.2

MLM2020

62

45

45

39

M5

23

18

20

48

50

M6

5.2

MLM2505

70

45

53

40

M6

28

18

20

55

51

M6

5.2

MLM2525

70

45

53

47

M6

28

18

20

55

60

M6

5.2

MLM3205

86

45

64

50

M8

33

18

20

66

65

M8

6.7

MLM3232

86

45

64

58

M8

33

18

20

66

74

M8

6.7

MLM4005

106

70

80

63

M8

42

32

30

86

78

M8

6.7

MLM4040

106

70

80

73

M10

42

32

30

86

93

M8

6.7

MLM5010

130

75

100

75

M10

52

34

30

105

93

M10

8.5

MLM5050

130

75

100

90

M12

52

34

30

105

112

M10

8.5

Hot Product

-

Video Support

-

Engineer Communication

-

Online Service

Keep In Touch

Do You Have Any Question?

-

25 Feb, 2025

Understanding The Role Of China Linear Guide Rail In Precision Engineering

China Linear Guide Rail Ball Screw Nut Assembly Exporter Producer China Linear Guide Rail plays a crucial role in modern...

-

21 Feb, 2025

Exploring The Benefits Of China Linear Guide Rail For Industrial Automation

China Linear Guide Rail Ball Screw Nut Assembly Factory Manufacturer China Linear Guide Rail has become an essential com...

-

14 Feb, 2025

China Linear Guide Rail: Key Features And Applications In Modern Machinery

Sale Wholesale China Linear Guide Rail Ball Screw Nut Assembly China Linear Guide Rail has become an essential component...

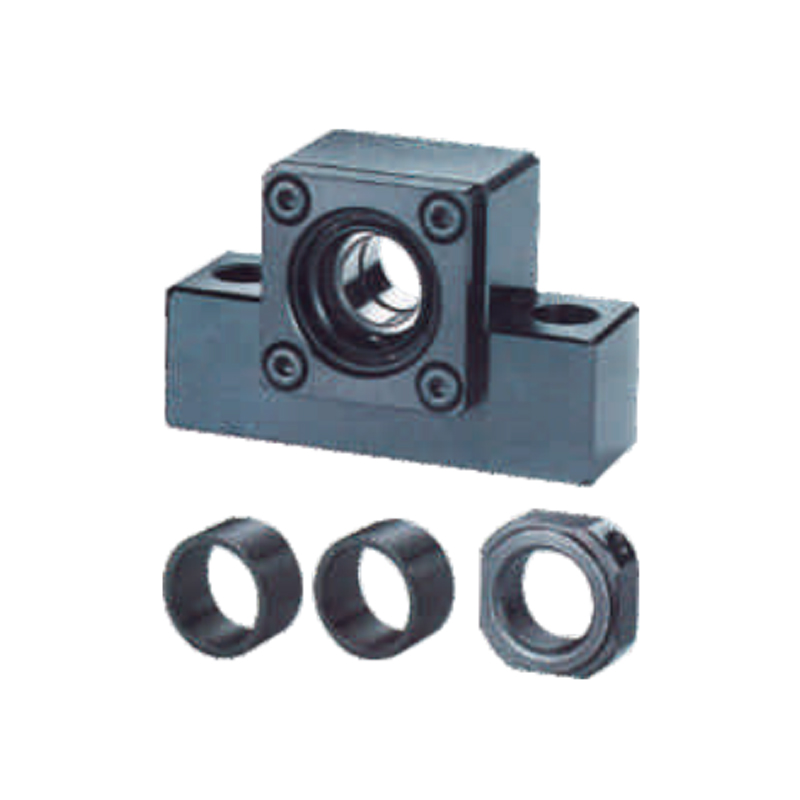

More Information About Ball Screw Motor Bracket Base

Zhejiang Huayu Automation Technology Co., Ltd. takes immense pride in introducing our cutting-edge product, the Ball Screw Motor Bracket Base. In our relentless pursuit of engineering excellence, we have designed this product with integrated processing, a feature that sets it apart from the rest.

Unparalleled Precision: At the heart of our Ball Screw Motor Bracket Base lies the quest for precision. We understand that in various industrial applications, especially in automation and robotics, the alignment of components is paramount. The integrated processing technology employed in our product ensures the maximum perpendicularity of the nut mounting surface to the base mounting surface. This level of precision is vital to the seamless operation of ball screw systems, where even the slightest misalignment can lead to performance issues and premature wear. With our Ball Screw Motor Bracket Base, the perpendicularity of both sides reaches a remarkable 0.01, surpassing industry standards.

Enhancing Reliability: Reliability is the cornerstone of any industrial component. Our Ball Screw Motor Bracket Base is constructed with durability in mind. By achieving a perpendicularity of 0.01, we not only guarantee reliable performance but also extend the lifespan of your equipment. This is particularly important in applications where precision and consistency are crucial, such as CNC machines, 3D printers, or robotics.

Versatile Applications: The versatility of the Ball Screw Motor Bracket Base is another noteworthy feature. It can be seamlessly integrated into various systems, from linear motion systems to rotational systems, ensuring that your automation or manufacturing processes run with utmost efficiency. The precise perpendicularity it offers makes it an ideal choice for any application where accuracy matters.

Quality Assurance: Zhejiang Huayu Automation Technology Co., Ltd. is committed to quality assurance. Our products undergo rigorous testing and inspection to ensure that they meet the highest standards of quality and performance. We take pride in delivering products that are not only reliable but also consistent in their precision.

A Step Towards Efficiency: Efficiency is the lifeblood of modern industries. Our Ball Screw Motor Bracket Base contributes to increased efficiency in your operations. By maintaining the perpendicularity of the nut mounting surface and the base mounting surface, it minimizes the need for adjustments and fine-tuning, allowing your systems to run smoothly and consistently.

In conclusion, our Ball Screw Motor Bracket Base is a testament to our commitment to engineering excellence. Its integrated processing technology, coupled with unmatched precision, reliability, and versatility, makes it an indispensable component in various industrial applications. At Zhejiang Huayu Automation Technology Co., Ltd., we understand the demands of the modern industry, and our products are designed to meet and exceed those demands, ensuring that your systems operate with the utmost efficiency and accuracy.

Our Ball Screw Motor Bracket Base is more than just a product; it's a reflection of our dedication to technological advancement. The meticulous attention to detail in its design, from integrated processing to precision perpendicularity, showcases our unwavering commitment to engineering excellence. This bracket base isn't merely a component; it's a solution to the challenges that industries face today.

Zhejiang Huayu Automation Technology Co., Ltd. understands that precision and reliability are the cornerstones of modern manufacturing and automation. As industries evolve, so do their demands, and our product ensures that your operations meet these demands head-on. It's a testament to our promise of efficiency, accuracy, and durability.

English

English 中文简体

中文简体 русский

русский Español

Español